How 3D printers and lasers are reshaping the future of cooking

Reimagining the future of food

At a time when nearly every corner of our lives has been reshaped by smart systems, automation, and computational design, the kitchen remains surprisingly analog. Most of us still hover over a counter or stovetop for much of the process, relying on rituals that have changed far less than the technologies around us.

Cooking is intimate, sensory, and deeply human. It’s also time-consuming. The USDA estimates the average American spends over an hour a day preparing meals, and this was 10 years ago. Yet, for all the creativity that happens in our kitchens, how we cook has yet to meaningfully evolve.

That tension—the gap between how we cook and how technology can augment our experience—is where some of the most exciting innovation is happening. And it’s where a human-centered product ecosystem becomes essential.

Before becoming a Senior Design Engineer at Smart Design, I explored this intersection during my doctoral thesis at Columbia Engineering. My research bridged culinary science, robotics, and emerging technologies. I’ve been exploring a deceptively simple question: What if robots could cook for us?

3D printing as the next kitchen innovation

Traditional cooking is simple, messy, and a hands-on process. By contrast, 3D printing offers three qualities the kitchen has never truly had:

Complexity

The ability to build intricate structures and geometries that humans would have trouble crafting with their hands.

Customization

The power to tailor meals to personal preferences, dietary needs, or constraints every time.

Creativity

The freedom to craft new flavor profiles, localized textures, and food experiences using a software-driven approach.

But food does not assemble the same as 3D-printed plastic. It isn’t a single material or even two. It’s dozens of ingredients, each with its own chemistry, viscosity, and behavior under heat. Bringing them into a single system requires more than engineering skill; it requires rethinking the entire cooking process.

This is where a systems approach is critical. It’s about understanding not just the mechanics of how something works, but how humans will meaningfully engage with it.

Building the system: From vision to prototype

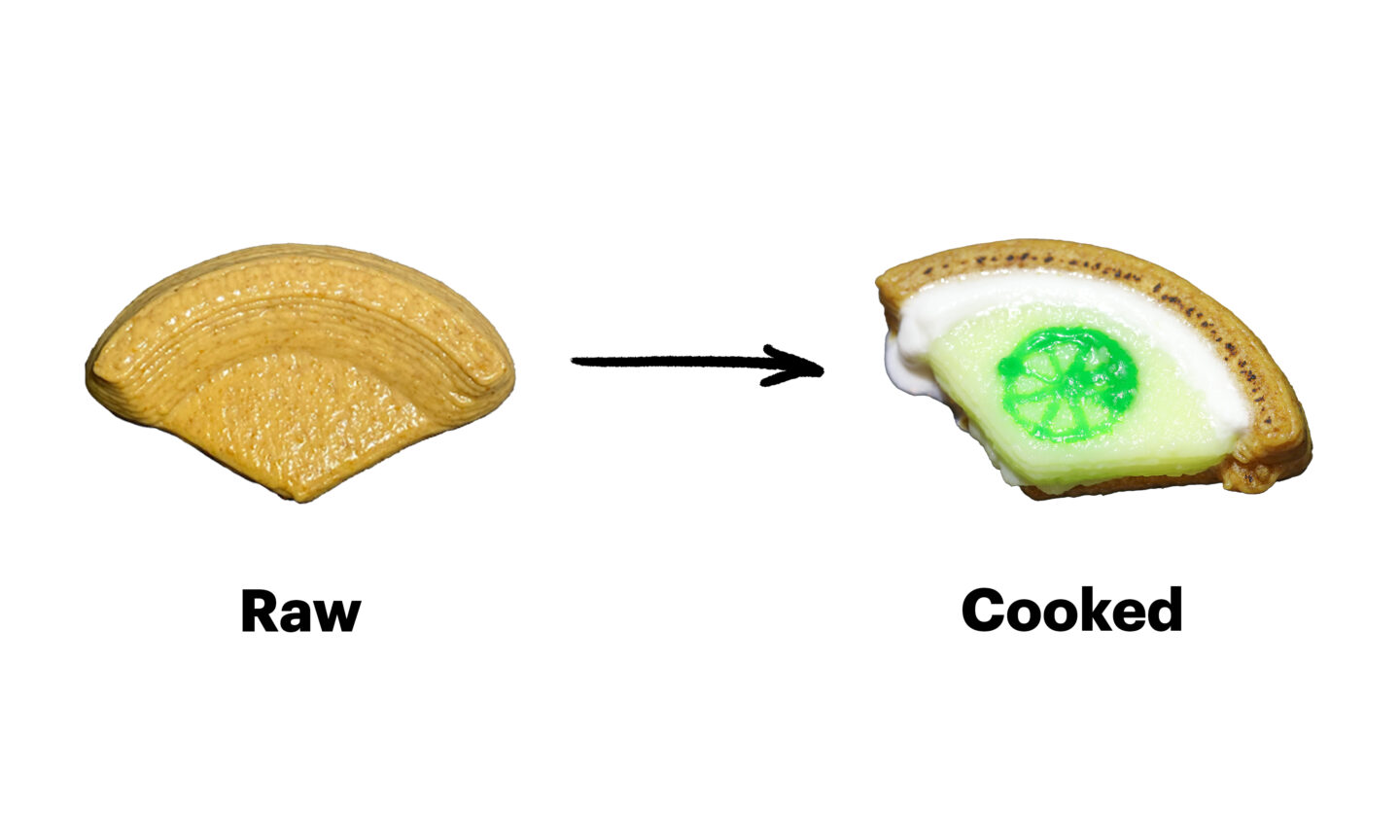

Early conceptual models envisioned a carousel-like appliance holding more than twenty ingredients, each ready to be dispensed, layered, heated, and assembled into a food structure. Over time, that vision became a fully functional prototype. A compact machine capable of printing with up to 18 unique ingredients and cooking them simultaneously using dual lasers.

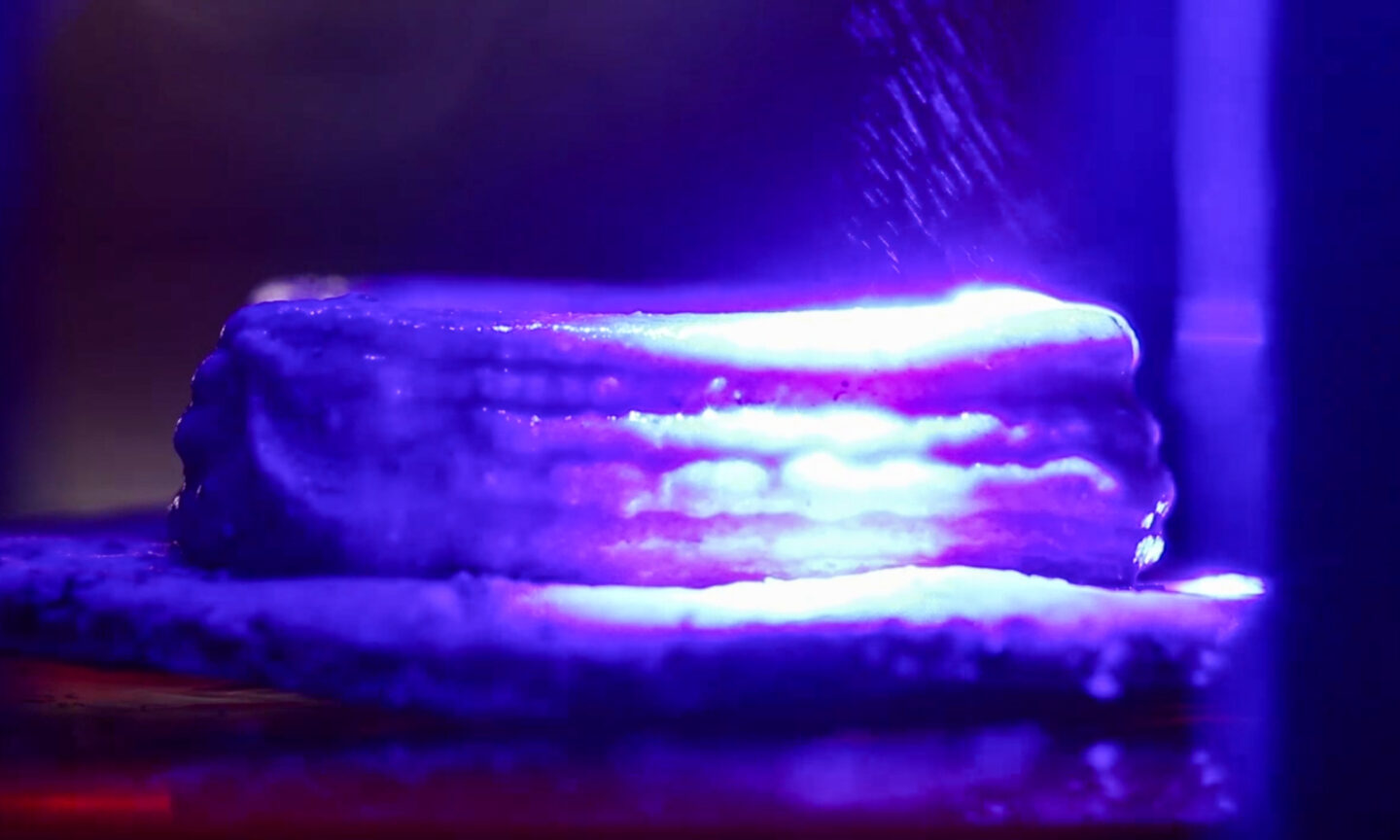

Unlike ovens that blast every part of a dish indiscriminately, lasers can brown a millimeter-thin surface, soften an inner layer, or firm up a structure without affecting everything around it. Laser cooking is a precise, targeted form of heat.

The result is an unprecedented level of control. You can 3D print a piece of dough and brown it evenly. You can build alternating layers of tofu and curry, then crisp just the top. You can create the complex architecture of a cheesecake, complete with differentiated textures.

And because cooking power can be applied exactly where needed, “digital” chefs can begin to solve one of the most persistent challenges of food printing: texture.

The core consumer challenge

When people taste printed food for the first time, their reaction is almost never about the flavor. It’s about the feeling.

“It tastes good—but it’s mushy.”

“I wish it were crustier.”

“It needs more bite.”

Texture drives trust. It shapes whether a visually stunning dish actually feels enjoyable, or edible.

To address this, a custom testing system capable of precisely measuring elasticity and structural integrity across printed samples was developed. By varying laser-cooking patterns—every layer, every other layer, every third layer—clear signatures were generated, showing where firmness improved, how heat traveled, and where structural weaknesses emerged.

Putting it into practice

To demonstrate what this approach can truly deliver, our research team pushed the boundaries with a 14-ingredient, three-course printed meal. Each ingredient modeled in CAD and built layer by layer. This marked the most ingredients ever printed into a single edible structure.

The breakthrough isn’t about novelty. It marks the start of a shift in how we create food. Chefs could experiment with entirely new textures, food services could tailor meals for individual needs, and people in demanding environments, from long-mission crews to clinical patients, could experience more variety and dignity in what they eat. And most importantly, none of this requires futuristic ingredients. It comes from better control, sharper precision, and thoughtful design of ingredients available today, but prepared via machine.

The new frontier of digital cuisine

When bringing emerging technologies into the real world, it’s important to keep the human at the center of these complex systems. This work exemplifies exactly that: connecting deep research, hardware innovation, software orchestration, and human expectations into something coherent and usable.

Cooking will always be human. But emerging technology and systems thinking can enhance the tools we use and alter the preparation processes. As 3D food printing becomes increasingly feasible, the question moves from “Can it work?” to “How do we make it valuable for people?” That’s the kind of design challenge we love taking on at Smart.